© WONDERTECH . All rights reserved. WonderTech International Energy Co.Ltd.

Terms of Use Notice | Privacy Policy

INTERNATIONAL ENERGY CO. LTD.

WTE G2500X

reduction of carbon emissions

WTE G2500X

Produces the most valuable by-products

WTE G2500X the most safe system

he most safety system

WTE G2500X the most efficient system

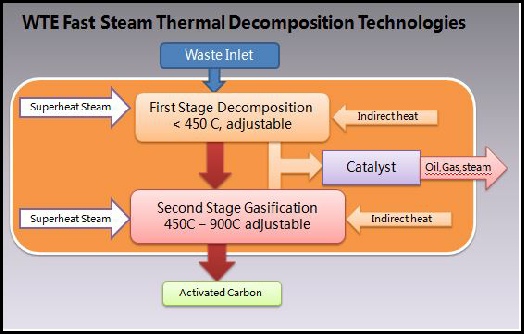

The key Features Of WTE Continuous Fast Steam Thermal Decomposition Technologies :

WTE is a proprietary technology which combines the Steam Direct-Heat and Indirect-Heat Pyrolysis technologies into one system and further incorporates a unique two stage pyrolysis and gasification process into the system. It encompasses all of the efficiencies of the various pyrolysis systems into one system, while eliminating any negatives that each one of those may have individually.

- A leading edge system, capable of processing multiple types of organic wastes which will be converted into high quality by-products.

- Safe and high energy efficient system, low cost and high investment return.

- Air pollution free, reduces by 80% the carbon emission when compared to an incinerator. It is the most environmental friendly system.

WONDERTECH announces the next generation system called “WTE G2500X” in 2012. It is focus on multiple types of Waste, such as MSW, Hospital Waste, Food Waste, Sludge, E-Waste, Landfill Recovery and etc.

WTE Two Stage Technology

The ability to mitigate an extensive variety of waste materials

Traditional pyrolysis technology is a one stage process. It can only handle one  kind

of uniform organic material during the same process. Also, it has to change the thermal

condition to match the uniform organic material, or it cannot completely crack or

decompose the organic matterials. The carbon residue will contain organic composition.

These by-products are not marketable to the industry. That is why most pyrolysis

systems are only used on one specific material such as used tires, rubber, and plastics.

They are not applicable for mixed or varied feedstock materials. Where there is a

variety of waste materials, a one stage process is not effective. Most waste in the

waste management field is mixed waste materials of un-predictable composition, such

as MSW, Hospital Waste, E-Waste and etc. WTE is the only effective technology for

mix waste materials.

kind

of uniform organic material during the same process. Also, it has to change the thermal

condition to match the uniform organic material, or it cannot completely crack or

decompose the organic matterials. The carbon residue will contain organic composition.

These by-products are not marketable to the industry. That is why most pyrolysis

systems are only used on one specific material such as used tires, rubber, and plastics.

They are not applicable for mixed or varied feedstock materials. Where there is a

variety of waste materials, a one stage process is not effective. Most waste in the

waste management field is mixed waste materials of un-predictable composition, such

as MSW, Hospital Waste, E-Waste and etc. WTE is the only effective technology for

mix waste materials.

WTE (Continuous Fast Thermal Decomposition) has developed a two stage decomposition technology specifically designed to mitigate mixed waste. The first stage acts as a decomposition mode. It converts most of the organic composition to fuel at the critical cracking stage. To obtain the greatest amount of fuel oil is the prime function during this stage. The temperature in the first stage is under 450C and could be adjustable. The second stage acts as gasification, deep pyrolysis, carbon activated, and fuel gas synthesis system. The purpose of the second stage is to completely de-compose the organic compounds. The processing temperature in the second stage is adjustable between 550C ~ 900C. With the patented two stage technology, the WTE system has the ability to deal with different kinds of organic waste. The WTE system is not only an energy converting system but also the best waste management system available. It can be utilized by industries to produce carbon black and fuel. It also can be utilized for waste treatment to reduce CO2 emissions and maximize profits and is the best solution to replace incinerators.

The Highest Energy Efficiency Rating

Traditional pyrolysis technology uses the application of indirect heat to a thermal reaction chamber. Because the thermal conductive surface is small, it takes a significant amount of time and energy to decompose the organic compounds resulting in low efficiency. The other disadvantage is the problem of heat being applied from the surface to the interior of the feedstock material. When the heat contacts the surface of the material, it forms a crust which hinders penetration of heat to the interior of the material. This crust will result in an incomplete de-composition of the organic compounds. The carbon residue will also contain remnants of the organic compounds and creates the secondary waste.

To solve this problem, the WTE patented system uses steam as the main source to directly heat the material. It can easily bring heat penetrated to the interior of the materials so as to more completely de-compose the material. To generate the steam heat source required uses more energy, to overcome this problem, the WTE system uses a unique energy recovery technology to generate steam by waste heat and create an indirect heating chamber from the same waste heat source. The heat source comes from the fuel gas produced from the waste pyrolysis. The reaction chamber will be heated by steam and with indirect heat at the same time. It will increase the efficiency of energy use up to 85%. When the system commences pyrolysis to generate the fuel gas, enough fuel gas is produced to support the heat source for the system almost without any application of external energy thereby saving significant energy costs.

The Safest System

There are two pyrolysis conditions necessary in a thermal decomposition system. The first is a vacuum condition. During this condition, the organic compounds will decompose to fuel oil and fuel gas. This fuel gas is rich in hydrogen and dangerous if contact is made with air. Hydrogen explosions can be a dangerous side effect of tradional pyrolysis. This is the reason why explosions can happen at the most pyrolysis plants.

The second condition is a high pressure condition. The higher the pressure, the higher conversion rate, however, the high pressure will create instability in the system and can become an unsafe and dangerous condition. The Asian market is reluctant to accept a high pressure process because of this hidden danger.

The WTE system uses steam as protection. The steam reacts with the carbon dust to generate more fuel gas and reduce the tar. The steam will clean the pipe to prevent corrosion. The steam will also form a protective shell to protect the fuel gas from making contact with the air even if fuel gas is leaking and provides protection by preventing the fuel from igniting.

- WTE Technologies: Steam protection, low vacuum requirement, continuous process, the safest system.

The Greenest Environmental System

WTE does not burn waste like an incinerator. To deal with complicated wastes such as MSW, Hospital Waste, E-waste, WTE has three processes to eliminate air pollution and completely eliminate the toxic by-product Dioxin. The first process is the WTE decomposition process. It keeps most of the carbon as a by-product thereby reducing the CO2 emissions up to 80%. It creates a special reactive environment to prevent Dioxin happening. The second process is called ”GASTEC”. It is a complicated fuel gas cleaning system. It not only has multi-stage condensers but also includes a gas cleaner to remove HCl, H2S, Dust, NHx, and Mercury. It will provide the system with clean fuel gas as a heat source.

The fuel gas will be burned in a 1200C heating chamber and will destroy any possible toxic material that may leak from GASTEC.

GASTEC includes an oil-water separator, oil filter system, and water treatment system. It treats the waste water and recycles the water back into the system. This waste water can be recycled when dealing with the material that do not contain chlorine such as waste tires, or certain plastics excepting PVC. If the waste materials contain chlorine such as MSW, Hospital Waste, E-waste, PVC, the water must be chemically combined with a salt creating chemical and discharged and replacement water added.

| G2500X |

| G1000 |

| M500 |

| H300 |

| History |

| WTE Core Technologies |

| Technical Comparision |